iAirAudit app for iPhone and iPad

Developer: Michael Diehl

First release : 09 Jul 2014

App size: 10.31 Mb

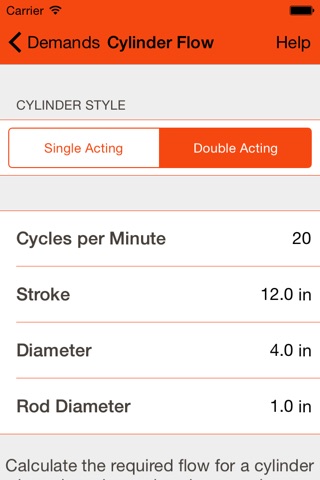

Air auditing is a challenging task that can yield big rewards. By determining the proper sizing of every aspect of the compressed air system waste can be eliminated and savings can be huge. The sizing of system components includes many variables, site conditions compared to manufacturer specs further complicates the task. A simple mistake like altitude correction may leave you with undersized equipment. iAirAudit is intended to help simplify the auditors job.

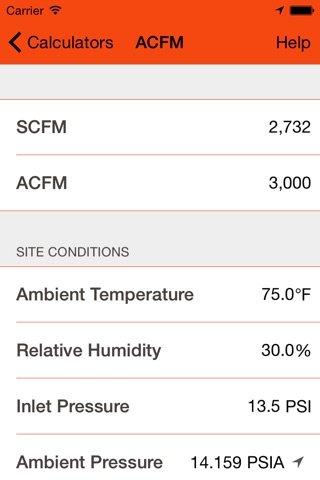

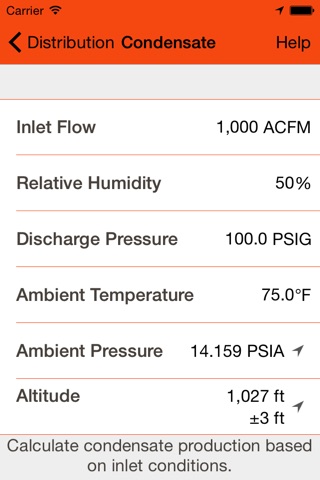

By creating calculators for specific tasks we can improve accuracy by reducing the possibility of mistakes. With features like automatic altitude correction using the devices GPS capabilities we improve the accuracy of your results right at the site location. If you are not on site you can simply use an altitude or ambient pressure by adjusting the app settings.

Our goal is to bring your most used tools right to your fingertips, without the scratch pad and at an affordable price. We have many more tools in development and with user feedback we can build a toolkit second to none.

•Altitude correction for calculations that can be corrected. Correction can be handled automatically with GPS or a manual altitude or ambient pressure can be entered.

•Support for both U.S. Customary and SI units with independent settings for pressure, temperature etc.

•The best default unit types are determined based on the user’s Locale setting for their device at the time of first launch.

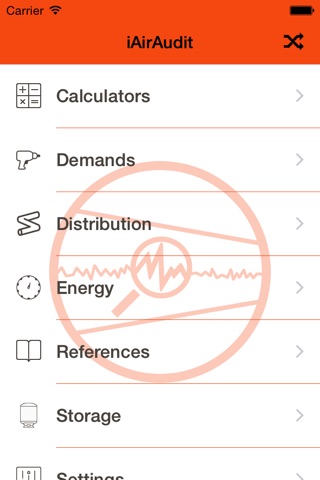

•Quick Conversions, quickly convert pressures, temperatures, flow rates etc.

•ACFM, SCFM conversion, convert between both based on site conditions.

•Load Percentage, find how much a compressor is loaded based on hour meter readings.

•Condensate Production, calculate the expected amount of condensate a compressor will generate.

•Pipe Diameter by Velocity, size pipe the correct way, by velocity.

•Energy Cost, determine how much a motor cost to operate annualy.

•Motor kW input, find the input power required based on motor nameplate data.

•Event Storage, calculate the storage required to carry a system through a demand event.

•Leak Rate, calculate the leak rate of a system based on system capacity and pressure decay time.

•Glossary, terms used often in the industry.

•Motor FLA chart, motor full load current based on data in the NEC table 430.250

•Galvanic Corrosion chart, determine the galvanic corrosion risks of different metals.

•Pipe Properties chart, various data on pipe including ID, OD, internal volume etc.

•Oil Carryover, determine the expected Oil Loss based on compressor specifications and run time or determine the oil carryover density (in PPM) based on the Oil Loss volume.

•Many builtin color schemes and support for custom logos imported from your Photo Library.